Made in Germany

Free Delivery

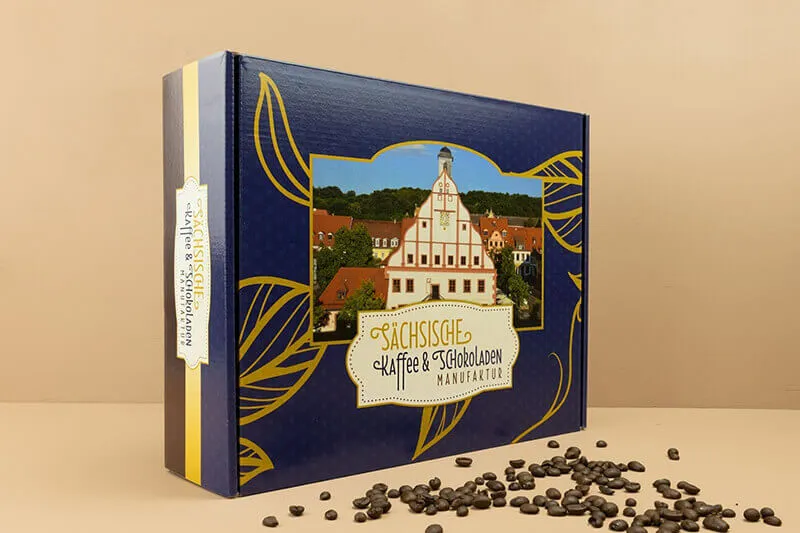

They should protect your products so that they survive the transport from you to your customers undamaged. And they should create positive experiences - through a high-quality look, pleasant feel and a unique unboxing experience.

Shipping boxes have to perform a lot and are in demand as never before. Our customizable product and shipping packaging meets all requirements, from reliable protective function to unique design:

In 2020, Deutsche Post alone delivered more than 1.6 billion parcels. In total, the number of shipments that all courier, express and parcel services transport yearly in Germany is more than 3 billion. Shipping boxes play a prominent role in this.

This is because shipping boxes offer a variety of excellent features for transporting a wide range of goods, making them the ideal choice for safe shipping.

STABLE & VARIABLE

Stable corrugated cardboard provides optimal protection for the packaged goods on the road. At the same time, it is light enough to enable economical shipping, can be easily printed and finished, and can be adapted to your individual requirements in almost every way. From the size to the type of base, with us you enjoy all the freedom in the design of your shipping and product packaging.

SUSTAINABLE

In addition, our corrugated cardboard shipping boxes are a sustainable packaging product. The boxes are made from 100 percent recycled paper. And after use, they can be recycled completely. With the shipping boxes from packaging-warehouse you get an excellent product that meets all the requirements of contemporary, efficient and sustainable packaging.

To ensure that products can be transported cost-efficiently and safely, shipping cartons should fit the product perfectly. At packaging-warehouse, we are specialized in making even complex processes such as the configuration of an individual shipping box as transparent and clear as possible. With the help of our intelligent configurator, you can clearly coordinate all the adjusting screws - no matter whether you are already a professional in the field of packaging or are new to the subject.

The smart configurator already makes some settings automatically to make the entire process as clear and simple as possible. For example, the printing technology that is the most favorable solution for the desired order quantity is always selected. Of course, you can change these settings at any time.

Another point that makes our service stand out is the cost-efficient realization of short runs thanks to digital printing technology. The flexibility of digital printing means that even individually printed short runs are possible, for example with consecutive serial numbers.

Thanks to our express production, your order can be produced in just 5 business days and thanks to the free formats can be produced in exactly the format that suits your product.

According to the Verband der Wellpappen-Industrie e.V. (Association of the Corrugated Cardboard Industry), corrugated cardboard accounts for around two-thirds of all transport packaging used for shipping goods in Germany. Foils follow only at a far distance - more than 50 percent separate the two packaging materials. Around 6 million tons of corrugated cardboard were produced in Germany in 2019. This corresponds to over 10 million square meters that were processed into transport packaging.

Because of their versatility, corrugated cardboard shipping boxes are used in almost all industries. Because different requirement profiles of trade and industry pose no problems for the number 1 transport packaging material. Whatever you want to pack and ship: it's in good hands in a corrugated cardboard box!

The food industry is the largest customer for corrugated cardboard transport packaging. Almost all foodstuffs can be safely shipped using such shipping cartons. In this case, that means:

Baked goods, candy, flour, sugar, pasta, rice, beverage bottles - with our shipping boxes you can safely and efficiently pack a wide range of different food and beverage products.

Other important customers for corrugated cardboard transport packaging are the chemical industry and agriculture. For the products from these two industries, the protective function also means above all preventing possible migration - but in both directions.

The products of the two sectors are to be protected from external influences, for example moisture. Conversely, in many cases it must be ensured that these do not pass through the barrier of the packaging to the outside (for example, potentially hazardous substrates, fertilizers, etc.).

This often calls for a robust material for the packaging materials that can cope with heavier weights if necessary. Here, corrugated cardboard can also keep up without difficulty. With the right combination of suitable flute and base type, our shipping boxes can handle shipping weights of up to 32 kilograms.

Online retailing continues to boom - not least because everything from luxury items to everyday objects can be purchased via digital channels. Popular items include a wide range of electronic devices.

These vary greatly in size, shape and weight, which is why transport requires packaging that can be adapted to the product in question:

The numerous design options also help to ensure that your shipping boxes convey the high-quality packaged goods inside even before they are unpacked. For example, with unique printing and/or special finishing.

Not all corrugated cardboard is the same. Although the name-giving principle is always the same, different versions of the flutes are differed. Depending on the structure, the individual flutes are more suitable for certain applications. In our assortment, you can therefore choose between several waves - and thereby assemble the shipping boxes that have the optimal properties for your needs.

WHICH SHAFT DO YOU NEED?

Basically, corrugated cardboard is available as a 1-corrugated or multi-corrugated (2- or 3-corrugated) variant. More flutes always mean more layers and therefore more stability. So the larger your shipping box and the heavier the contents, the more flutes should be used. In addition to the positions, the different types of waves each have their own wave divisions and wave heights. This refers to how high the wave is and how far apart neighboring wave peaks are.

At packaging-warehouse we use E, B and EB flutes for our shipping boxes. This guarantees a wide range of possible applications.

At packaging warehouse you will find a wide range of corrugated cardboard folding boxes:

Folding cartons are also very easy to fill automatically and are available with many different variants:

Our shipping packaging is also available with different base or closure options:

Reinforcement for our product and shipping boxes

In order to fix products or present them appropriately, at packaging warehouse you can rely on a wide range of inlays and slipcases that can be perfectly combined with all boxes and cartons:

Reliable protection, sustainable materials, efficient storage. Our shipping boxes score with many advantages. They become even more attractive - in the truest sense of the word - because you can design them according to your own ideas. Design your own shipping box simply and easily with our configurator!

As with all products in our range, the same applies to our shipping boxes: If you only need small quantities, that's no problem at all. And regardless of the order quantity, our fast production times ensure that you don't have to wait long for your shipping and product packaging. Best quality in a short time - we at packaging-warehouse make it possible for you!

To protect your cardboard and the printed image even better from scratches, you can choose between two finishing options in our configurator:

The thin layer of varnish on your shipping box ensures that the print image is not damaged by scratches, dirt or even liquids or similar, but it also has another advantage: the gloss makes the print stand out even better and also protects it from fading due to sunlight. The printed image itself appears more detailed and high-quality due to the varnish. Our protective coating is available in both matte and gloss.

Here, the cardboard is not sprayed with a varnish but covered with a thin foil. This makes the outside even more resistant to external influences and the printed image is also optimally protected against scratches and UV radiation. Our laminate is also available in matt or gloss. It offers maximum protection and, like the protective coating, enhances the print image.

Both finishing options are available in our smart configurator and give your shipping box a classy and protective finish.

Q: What is the minimum number of cartons I need to order?

A: We want to be the perfect partner for companies of all sizes - from large corporations to start-ups. Especially for small companies that may even be in the market entry phase with their product, ordering large quantities is not economical or often not realizable at all. At packaging-warehouse there are therefore no minimum order quantities. Starting from one piece we realize the perfect packaging solution for your business.

Q: What are the sizes of shipping boxes?

A: At packaging-warehouse you have the possibility to freely determine the format of your shipping box. For this you have the following dimensions at your disposal: Length 60 - 700 mm, width 60 - 700 mm and height 15 - 250 mm. This makes it possible to configure a variety of formats - from particularly small to particularly large shipping boxes.

For us, sustainability is a central idea of our company philosophy. Therefore, all our materials are of a sustainable nature:

Our corrugated cardboard or corrugated cartons are made from renewable raw materials and can therefore be completely recycled. Paper (the raw material of corrugated cardboard) originates in forests, which are managed sustainably. Conscientious forestry management ensures that the tree population in Europe is constantly increasing. This ensures that our boxes are produced in harmony with nature.

In addition, our corrugated cardboard is characterized by resource-saving and energy-efficient production. Almost no trees are felled in corrugated cardboard production. The primary raw material for paper production is obtained from broken and thinned wood from managed forests. Germany is the European leader in corrugated cardboard production.

Another advantage of corrugated board is its property for recycling. After removing the adhesives, impregnations and other chemicals from the corrugated boxes, they can be almost completely recycled. Approximately 80 percent of the annual production volume therefore consists of recycled material. Cartonboard fibers can theoretically be recycled up to 25 times. However, the fibers shorten with each new run. Therefore, fresh fibers must always be added in corrugated cardboard production to prevent a loss of quality in the end material. In Germany, however, just 20 percent fresh fibers are used for the corrugated base paper.

Energy consumption is also clearly lower in corrugated cardboard production than in glass recycling. In addition, there is less chemical waste than in the recycling of plastics.

Offset printing is based on the technique of lithography and is known as indirect printing. The ink is first transferred from a physical printing plate to a blanket cylinder and from there it reaches the surface to be printed.

This takes a little more time because a separate printing plate is created for each color and coating. This makes the print image particularly high-quality.

Due to the effort involved, however, offset printing is only really cost-efficient above a certain order quantity, as further costs are incurred here for creating the printing plate and for consumables.

On the other hand, the print result with the offset process is of the best quality.

With digital printing, data is transferred from the cloud or via a USB stick, for example. The advantage here is that since the process is not as costly as offset printing, shorter runs can also be printed cost-effectively.

In addition, thanks to digital data transmission, it is also possible to make individual adjustments within a series without any problems, as is the case when printing a consecutive serial number, for example.

With offset printing, this would involve very high costs as well as a considerable amount of time, as a new printing plate would have to be made each time. Therefore, digital printing is the ideal solution for printing shipping boxes in smaller runs of 1 - 500 pieces particularly well suited.

A third printing process that we also offer is so-called "flexographic printing" - another direct printing process that is particularly suitable for printing large runs of 25,000 cartons or more.

Our intelligent configurator automatically selects the most cost-effective method depending on the quantity you order when you put together your desired product. Of course, you can change this at any time and adapt it to your individual wishes.

Configuring an individual shipping box can be very complex. At packaging-warehouse, we have made it our mission to make this process as simple as possible, yet flexible and with maximum control. We achieve this with our intelligent configurator, which even company managers without much previous knowledge in the field of packaging configuration can use to quickly achieve a professional result.

After you have decided on a specific product, for example a shipping box with a hinged lid, you can first specify the desired quantity. If you make changes in this field (as well as in every other field), the offer is automatically adjusted. This way you always have an overview of the costs.

Then you can choose one of the standard formats or configure the size of your box within the available minimum and maximum values.

In the next step, you decide on the material. Here you can choose between different flutes (E-flute, B-flute or EB-flute) in different color combinations. Then you select whether and how the cardboard is to be printed. Separate fields are available for printing on the inside and outside.

For the print on the outside you can choose between 4/0-color Euroscale and 4/0-color Euroscale + white. For the inside print you can choose between 1-color black or 4/0-color Euroscale.

This is followed by two selection fields for finishes. First, you choose whether you want a protective coating (matte or glossy) for your shipping box. Secondly, you can select the protective laminate that suits you best. Here you also have the choice between matte or glossy, but also soft-touch laminate is available.

The last steps within our intelligent configurator are the additional options and the delivery time. As already mentioned, a basic data check is performed for every print job. In this process, the data format, font and font size as well as the formatting of the color space are checked by our experts as standard. With the additional option Professional Data Check, we also check the margin trim, safety margins, spot colors, resolution, and line thickness.