Made in Germany

Free Delivery

The FEFCO code 0427 stands for packaging of a special kind. In terms of function and aesthetics, the hinged-lid boxes have everything that defines high-quality shipping boxes and product packaging:

They protect goods reliably from external influences, are resealable and ensure an appealing product presentation with their elegant design as well as the diverse design options.

Your individual FEFCO 0427 hinged-lid boxes:

The FEFCO-ESBO code is an internationally valid standard for the classification and description of corrugated cardboard and solid board packaging materials. Originally, the coding system was developed by the European Federation of Corrugated Cardboard Manufacturers (FEFCO) and covered only corrugated packaging. Today, however, the European Solid Board Organization (ESBO, former ASSCO) is also involved in the coding process. This means that solid board packaging is also covered by the FEFCO codes. Meanwhile, the FEFCO catalog contains around 200 different packaging materials with unique codes. Learn more about the FEFCO code here.

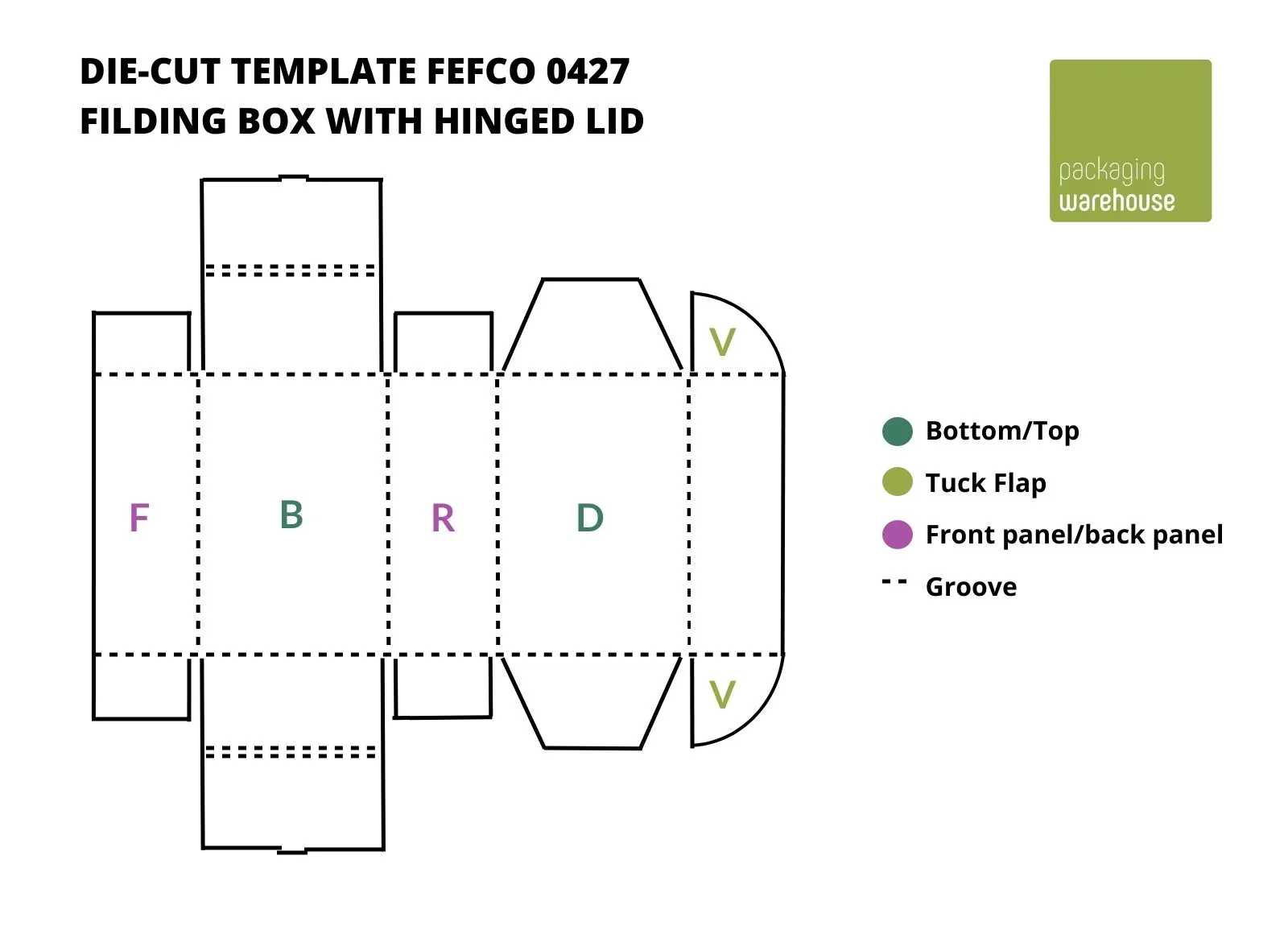

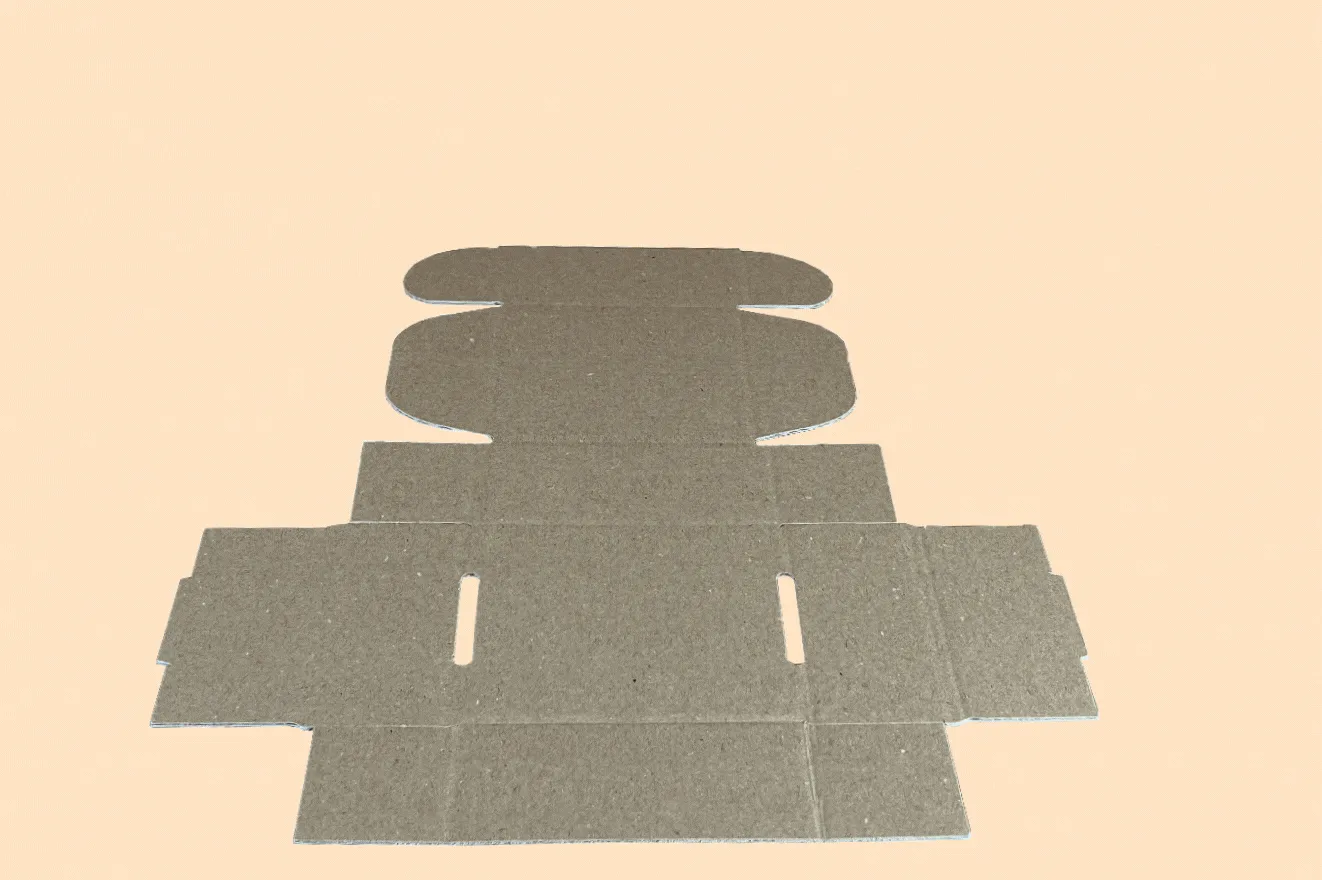

According to FEFCO 0427, hinged-lid boxes are a special form of folded envelope that usually consists of only one piece (or blank). In this case, all four side walls are firmly connected to the floor and each separated from it by a creasing line (for bending the walls).

The lid is an extension of the back panel and is folded forward from the back when closing. A special feature of the construction is the closure: the flaps of the outermost lid section are inserted into two slots on the longitudinal front of the box - and so serve as a reclosable locking device.

When setting up, first align the front and rear longitudinal walls horizontally. There are two small flaps on each of the two walls, which you bend 90 degrees towards the inside. Now put the long flaps of the bottom surface over them. To do this, bend the bottom flaps and insert their outer lugs into the slots on the bottom crease line.

The lid of this packaging is an extension of the back wall of the box. All you have to do is fold it over towards the front, pressing the two trapezoidal dust flaps lightly into the interior of the box. Finally, insert the two sealing flaps into the slots provided for them on the front of the box - and the goods are packed.

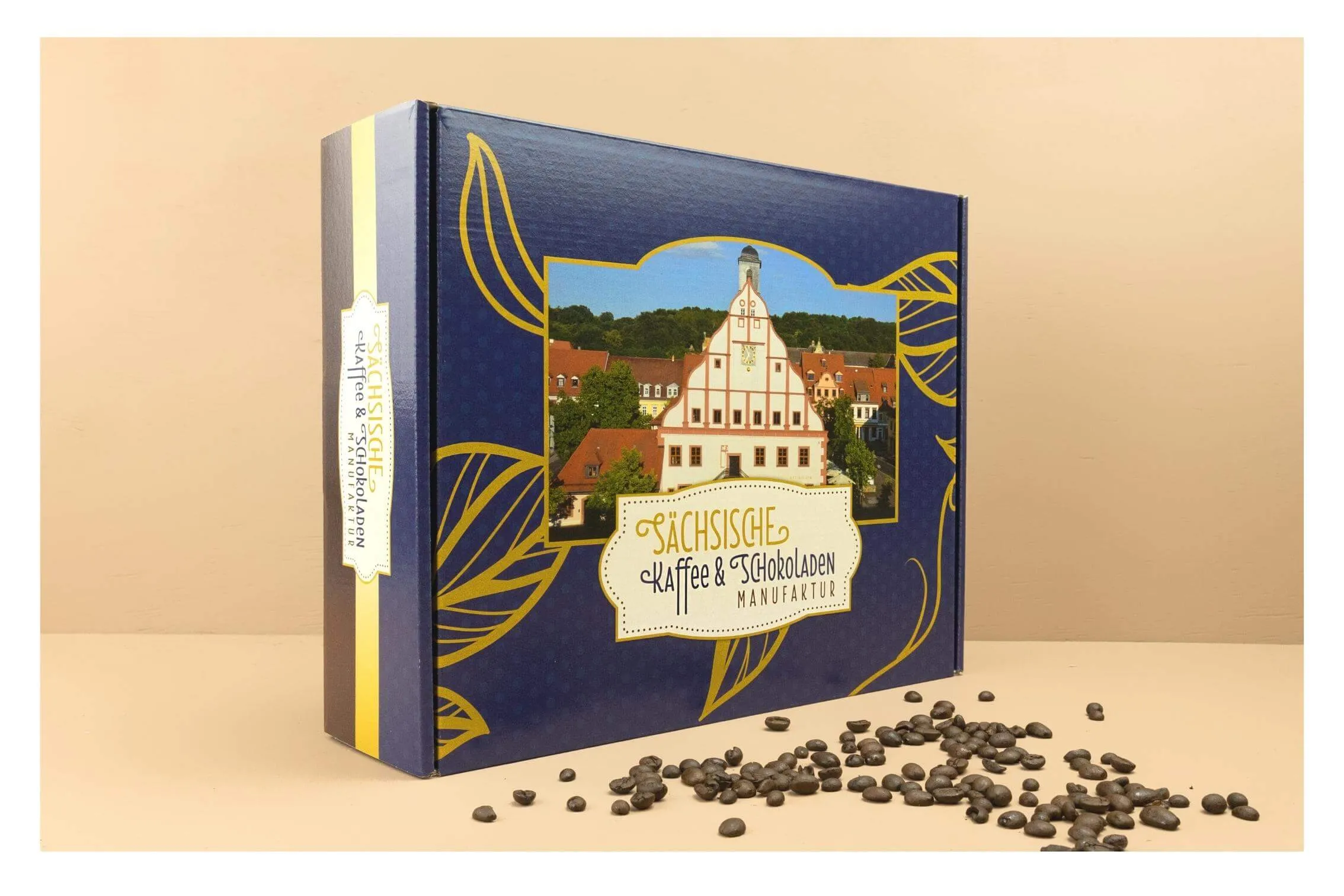

Hinged-lid boxes are the all-rounders among box packaging. Variants made of corrugated cardboard are a popular solution in e-commerce, for example. On the one hand, the solid base and thick corrugated walls provide a secure hold and goods protection. On the other hand, the boxes are elegantly shaped, resealable and customizable.

Cardboard design, on the other hand, is mainly used as product packaging. Here it is especially the aesthetic advantages, thanks to which hinged lid boxes are a very popular alternative to classic folding boxes. These come into their own especially when unpacking the goods, as the packaging is very similar to a gift box.

At packaging warehouse you can design folding boxes with hinged-lid according to your individual ideas. Our online configurator offers you various options in terms of

With just a few clicks, you can adapt your packaging exactly to your individual requirements. We then ensure a precise implementation - through the use of high-quality materials and production processes.

Regardless of whether you want boxes made of corrugated cardboard or cardboard, at packaging warehouse you always have the option of making your packaging sustainable.

However, how sustainable your packaging is in the end also depends on whether you provide it with a protective laminate, for example, or otherwise finish it using plastic.

Hinged-lid boxes offer a great amount of space for creative designs. This is because every square centimeter of the boxes can be printed with text, color and patterns - both on the outside and inside.

A printed inside is guaranteed to create a moment of surprise and help make unpacking your goods a real unboxing experience.

Thanks to modern digital printing technology, it is also possible to personalize and individualize your packaging. This means that you can order different designs within just one series.

For example, it is a good idea to add a sympathetic thank-you note to the inside of the cover, addressed to your customers by name - a small but effective gesture.

Both corrugated cardboard and pressed cardboard are ideally suited for the production of FEFCO 0427 type packaging. Thanks to its excellent protective performance, corrugated cardboard scores particularly well as a material for shipping packaging. Cardboard, on the other hand, is mainly used for product packaging.

The FEFCO codes only standardize the various designs of the packaging materials. Other characteristics, such as size, on the other hand, are variable. Dimensions between the following minimum and maximum values are possible:

Please note that the maximum values mentioned can not always be combined for technical reasons. In such a case, however, our online configurator will notify you directly.

At packaging warehouse, we basically use two different printing methods. Whether offset or digital printing is used is always determined by the run size, the desired format, and special requests for personalization.

While offset printing offers a price advantage for larger runs, digital printing saves both time and money for short and medium runs. Since the printed image is excellent with both techniques, we therefore always choose the more cost-efficient option for our customers.

The only exception: For technical reasons, only digital printing is used for printing variable data (i.e. changing designs within a print series).

There are several reasons that speak in favor of finishing. On the one hand, there is the protection of the goods. After all, applying a varnish or lamination always increases the resistance of the packaging, for example to fading and moisture.

Improving the visual and haptic properties also plays a role. After all, sensory stimulation plays a decisive role in shopping. Laminates and coatings also offer some possibilities here.

Depending on your wishes, we can use it to give your packaging a matte or glossy look. This is very easy to gain the attention of customers. With a soft-touch laminate, the boxes can also be enhanced haptically - for a pleasant touch experience.

CREATE PRINT DATA CORRECTLY

1. Configure the hinge-lid boxes with the help of our online configurator. First you determine the required number of pieces, the dimensions and all other desired specifications.

2. Edit the print template: After the configuration is complete, download our print template. You then design these according to your individual ideas. You can use a graphic program of your choice, such as Adobe Illustrator.

3. Send us the print data: There are two ways to do this. First, you can upload them to the shopping cart to send them directly with your order. On the other hand, it is also possible to submit the data at a later time. You will receive an e-mail with further information after your order.

You can find more tips and hints on our page about data structure for folding boxes and shipping boxes.

If you have any questions or are unclear about anything, our team will be happy to help you personally.

Mon – Thu: 8:00 AM – 5:30 PM

Fri: 8:00 AM – 4:30 PM

Email has been copied[email protected]